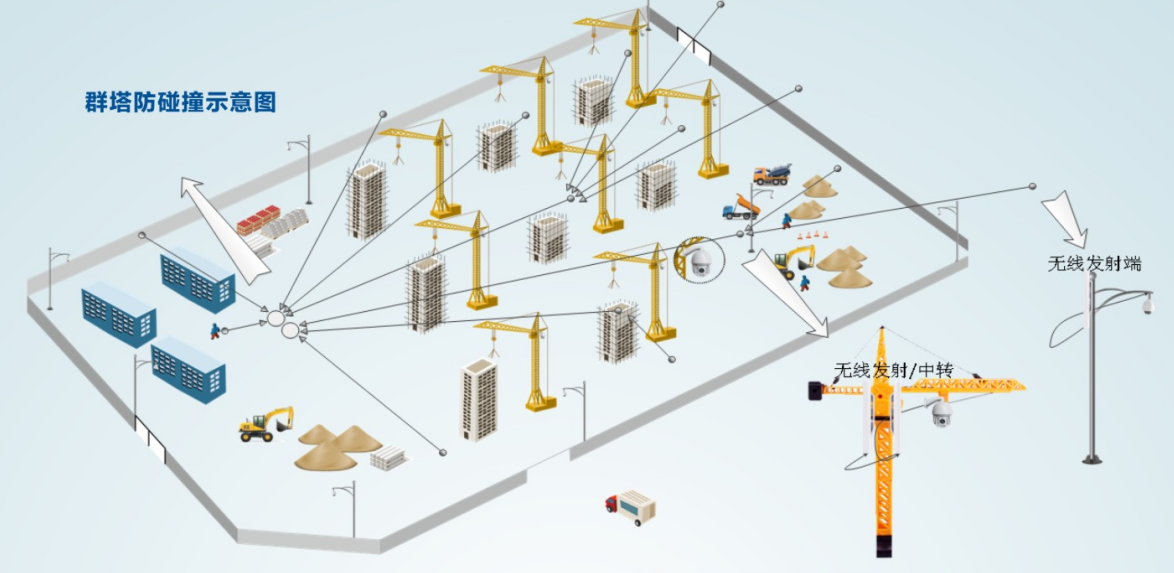

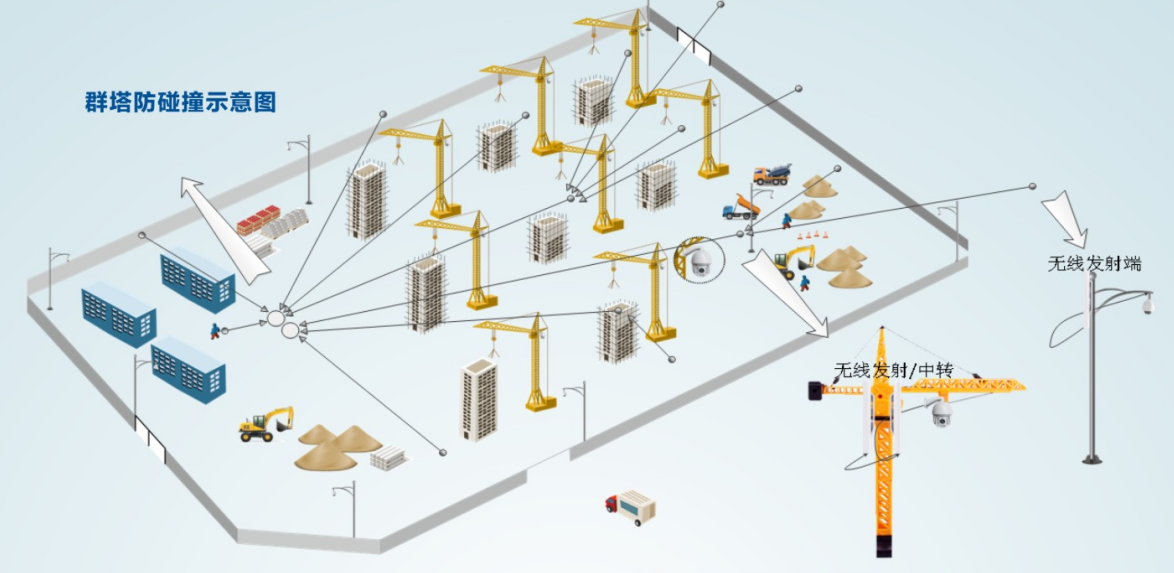

With the deepening of urban construction, the scale of various construction continues to expand, in order to meet the requirements of the construction period, multiple tower cranes operate at the same time, and there are multiple cross-working areas, using the traditional manual patrol, manual paper media, can no longer meet the requirements for the safe use of the project tower crane.

The use of information technology to realize the innovation of supervision mode and solve the problems of "weak supervision and backward supervision means" in construction projects has become an inevitable choice for project construction managers. Based on our anti-collision system, on-site drivers can receive collision alarms at the first time, and project equipment managers can receive SMS reminders of collision safety hazards. The implementation principle of this system is as follows:

1. Through the data transmission module, the adjacent tower crane establishes a local area network tower crane to transmit its own amplitude and rotation data to other tower cranes, and at the same time receives the amplitude and rotation data sent by other tower cranes in the monitoring system instrument, forming the mutual position and collision relationship of the tower crane;

2. In the event of a collision alarm, the following 3 conditions need to be met at the same time:

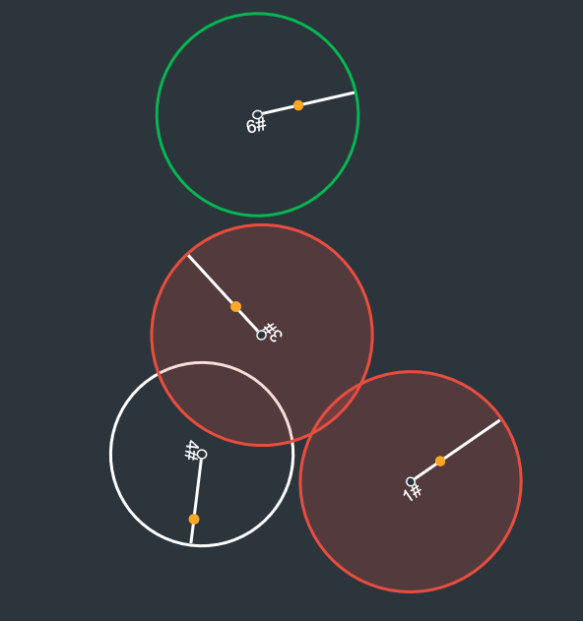

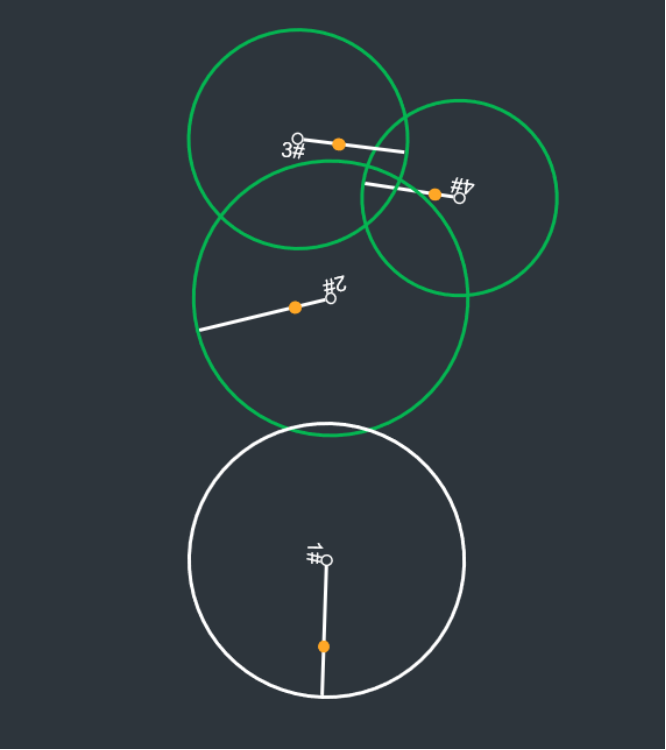

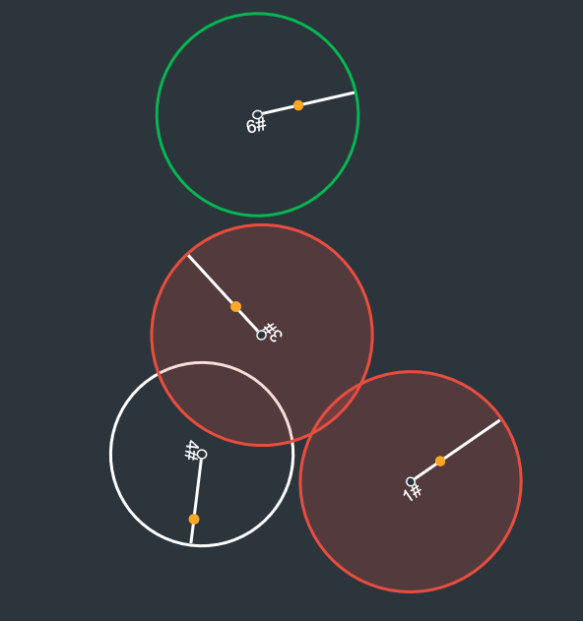

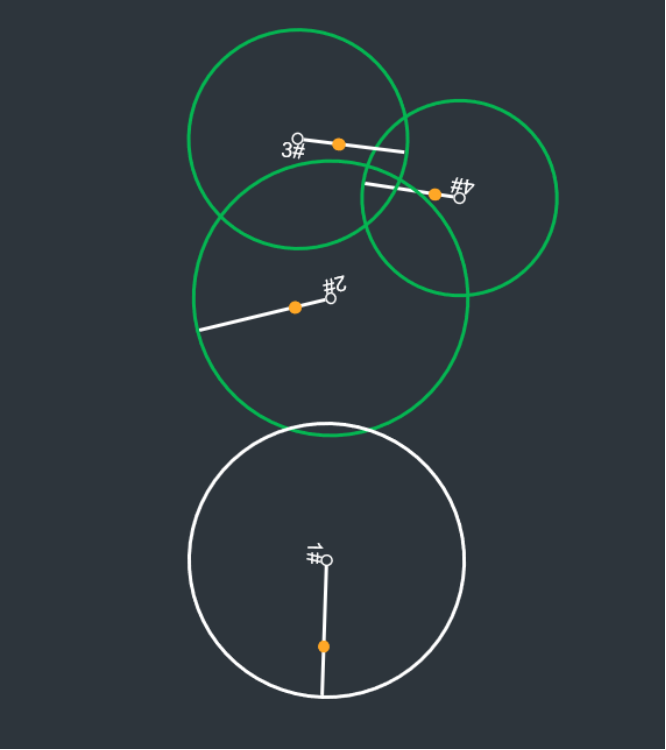

1) The relative distance of the two tower cranes is less than the sum of the lifting arm lengths of the two tower cranes;

As shown in the figure: the relative distance between the 3# machine and the 6# machine is greater than the sum of the lifting arm lengths of the two tower cranes, and there is no collision risk; The relative distance between the 3# machine and the 4# machine is less than the sum of the lifting arm lengths of the two tower cranes, and there is a risk of collision;

2) The boom of the adjacent tower crane enters the cross area at the same time;

3) At least one tower crane trolley enters the intersection area;

As shown in the figure: the two tower crane booms of the 3# machine and the 4# machine enter the cross area at the same time, and the alarm will not be triggered, because the height difference between the two is at least 2 meters when the tower is erected, and the big arm has no possibility of colliding on the same horizontal line, because no trolley enters the cross area, nor will it cause the collision of the high tower wire rope and the low tower boom; Only when the 3# machine or at least one trolley of the 4# machine enters the intersection area will the alarm reminder be carried out.

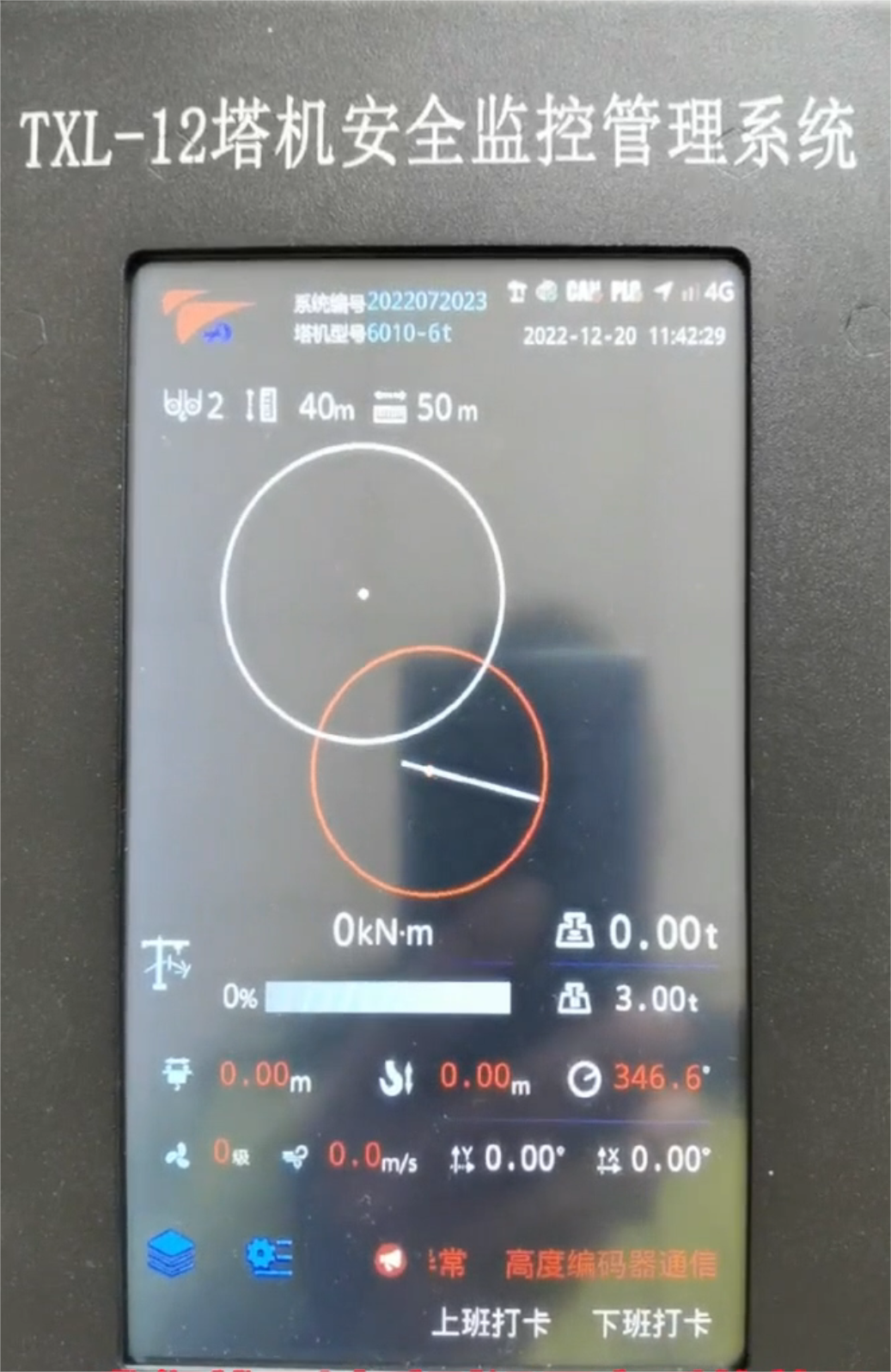

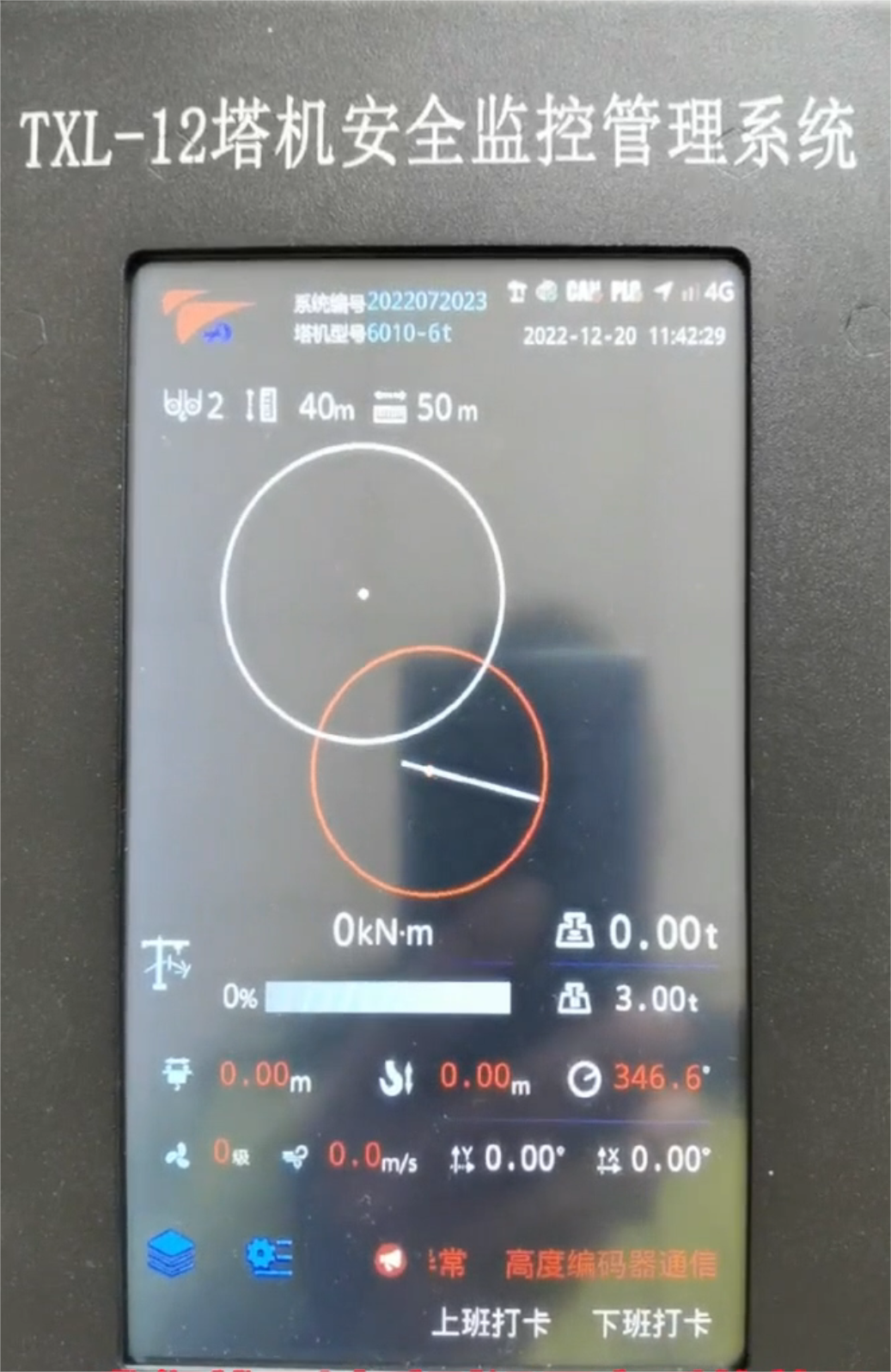

3. The driver can receive the collision alarm by installing a display instrument in the cab, and check the relative position of the big arm and the car of the adjacent tower crane in real time.

4. The project equipment administrator can receive and view alarm reminders through the mobile phone, or view the historical data through the computer, and obtain the driver's operation ability evaluation according to the tower crane operation data.

5. Based on this system, according to the sensor technology of tower crane manufacturers, add sensors such as weight, torque, height, wind speed, etc., which can realize the judgment of the effective status of the five safety protection devices of the tower crane and the all-round control of the working time, cumulative lifting weight and number of times of the mechanism.